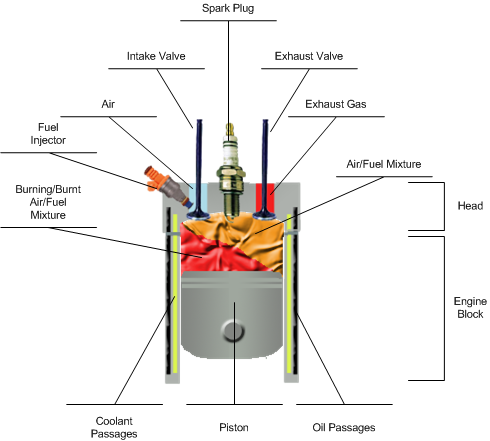

Spark Plug

When this receives around 20k volts, a spark is produced and causes the Air/Fuel mixture to ignite, pushing the piston downwards.

Intake Valve

The Camshaft, a.k.a. Bump Stick, opens and closes this valve for each cylinder independently. When this valve is opened,

atmospheric air is drawn into the cylinder due to the piston moving down.

Exhaust Valve

The Camshaft, a.k.a. Bump Stick, opens and closes this valve for each cylinder independently. When this valve is opened,

burnt air/fuel gases are pushed out of the cylinder due to the piston moving up.

Air

This literally is just atmospheric air.

This comment will cause concern with people who are familiar with carbureted engines.

This is because in carbureted engines, the intake manifold contains an air/fuel mixture,

but in fuel injected engines, this is not the case.

In fuel injected engines, the intake manifold contains atmospheric air.

Exhaust Gas

The air/fuel mixture is ignited by the spark plug, and this is the remains of that process.

Fuel Injector

The Powertrain Control Module, PCM, turns this actuator on and off. When this actuator is on, fuel is sprayed past the open intake valve

converting the air in the cylinder into an air/fuel mixture. Note: To meter the amount of fuel in the cylinder, the PCM controls how

long this actuator is on.

Air/Fuel Mixture

The Powertrain Control Module, PCM, controls the actual Air to Fuel ratio comprising this mixture. Generally, for best tail pipe

emissions, the PCM sets this ratio to 14.7:1 ( air parts : fuel parts ). If the PCM is trying to extract more power from the engine,

this ratio is around 12:1 or is trying to extract more economy from the engine, this ratio is around 16:1.

Burnt Air/Fuel Mixture

Once the spark plug ignites the Air/Fuel Mixture, this burning process transforms the Air/Fuel Mixture into the Burnt Air/Fuel Mixture

ending with it becoming Exhaust Gas.

Coolant Passages

The Engine Block and Cylinder Head contain vein like passages used to move Coolant through it. As the Coolant moves through these

veins in the metal, the Coolant is extracting heat from the metal, which reduces the heat in the metal.

Oil Passages

The Engine Block and Cylinder Head contain vein like passages used to move oil through it.

As the oil moves through these veins, drilled out ports

are reached where critical metal on metal components receive much needed oil. In addition, as the oil drips and runs down

back to the oil pan, it is pulling heat from the metal, which reduces the heat in the metal.

Piston

Each piston is connected to the crankshaft via connecting rod. These two later components are not

included in this diagram and will be discussed later. The Crankshaft is connected to the Transmission which then delivers

this energy to the tires. So, as the ignited Air/Fuel mixture expands, it pushes the piston down away from the head, which results

in the Crankshaft receiving rotational energy.

Head

This is also called the Cylinder Head. It contains all the components of the valve train, spark plugs, injectors, and sometimes

Camshaft(s).

Block

Often referred to as the Engine Block. It houses most of the parts that make of the internals of the engine.